FLOW CURVES – THE MATTER OF RELEVANCE

Published on 1 July 2016 by

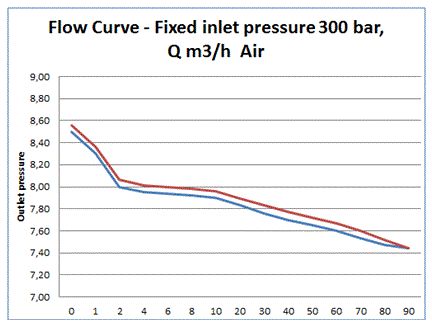

You remember, in the first article I placed on LinkedIn I spoke of the matter of relevance. How relevant is it to have minimal hysteresis or initial droop. Well, for selecting your regulator, such flow curve can tell you about the outlet pressure behavior at a constant inlet pressure and a changing flow rate.

In this curve, the blue line is the increasing flow line & the red line is the decreasing flow line.

A flow curve is set in a test environment, mostly on a gas like nitrogen or air, or on a liquid like water (as its characteristics stay very similar when put under pressure) under ambient temperatures. Mind, when you buy a regulator for liquid, it does not automatically mean, the flow curve you receive is made on a liquid test stand as well. Often it is made on a gas test stand. You may need to ask for this if desirable. The inlet pressure is fixed and then flow is added to the pressure regulator. The start of the flow has an effect on the behavior of your outlet pressure.

Right after the initial flow, a pressure drop is noticeable. This is called the "Initial Droop". After this initial drop the pressure will more or less stabilize over a given increasing flow rate. The flow rates at which the outlet pressure remains more or less stable is called the "optimal flow range". Then the pressure starts dropping again. This is called the "choke flow range". This is the area where you do not want your regulator to operate. When you size your regulator, it is best to have it well within the "optimal flow range".

Mind, besides a flow curve, one can also calculate the flow coefficient (Cv), though this says more about the maximum allowable flow capacity than about the optimal functioning at a given flow. Flow thus influences your pressure regulator behavior.

When continuing with the flow curve, the test stand decreases its flow again and then you will see the outlet pressure with a decreasing flow rate is higher than with an increasing flow rate. The difference between these two is called "Hysteresis". And then when the flow rate is decreased to zero, the outlet pressure has increased compared to the initially set outlet pressure. And this is called "Lock-Up".

Typically, a flow curve should be delivered by the manufacturer. As there are differences between flow curves from one to the other manufacturer, always check you receive a description with it and/or the axes are labelled and the line is specified. Some examples from GCE Druva & Kayser-Werk:

Two other terms we did not cover yet, "Creep" and "Decaying Inlet Characteristic".

"Creep" means the outlet pressure slowly increases, and this is normally something that happens over time. This is adjacent to a "Lock-Up" and is actually an indication your regulator is leaking. In such case, I would call my supplier and ask for a replacement.

"Decaying Inlet Characteristic"; the term actually says it all. Due to a lowering of the inlet pressure, something will to happen with the outlet pressure. And that is correct. It goes up. When you have a gas supplied to you from a cylinder, the inlet pressure sinks as the bottle empties or depletes. Your outlet pressure goes up. When working in a safe environment, it is advisable to check this number with your supplier to avoid any alarm in the system.

To summarize; make sure you work closely with your supplier to determine the best regulator and the best size for your application. Questions or you want to subscribe to our newsletter? Mail us: regulator@gcegroup.com