Automated Oxy-Fuel Cutting

With long-term experience in the development, production and application of machine cutting torches, nozzles and various accessories, GCE is a global leader in oxy-fuel cutting technology. Innovative solutions supported by several GCE patents are used to achieve the main target - many benefits for customers. The key words are high performance of the cutting process, excellent quality of the cut, easy handling with the equipment and long lifetime of the products. All that means short payback of investment to GCE products and consumables, made in Europe. The design of the products is based on GCE’s extensive knowledge and expertise in the area of oxy-fuel cutting, new types of cutting machines and control systems thereof, as well as on the requirements of the global metal-fabrication market represented by daily contact with large user-applications worldwide portfolio. Products are supported by pre- and after-sales services and extensive training program using GCE application centre or at the customer site.

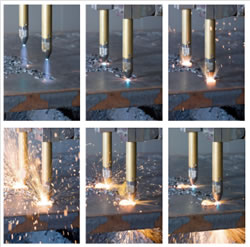

Steel plate piercing with GCE FIT+®

GCE machine cutters and nozzles give many benefits to users. The latest GCE development results in creation of innovative range of Tool-Free equipment which is represented by GCE FIT+® cutting system. Heating and cutting nozzles are fixed in the torch head by bayonet-lock without using wrenches, just with operator’s hand. One of the main benefits is possibility of hole piercing by oxy-fuel technology into the steel plates up to 150 mm thickness (*). With setting of proper parameters recommended by GCE the machine can pierce the plate smoothly and safe for the equipment and environment without expensive mechanical pre-drilling.

GCE machine cutters and nozzles give many benefits to users. The latest GCE development results in creation of innovative range of Tool-Free equipment which is represented by GCE FIT+® cutting system. Heating and cutting nozzles are fixed in the torch head by bayonet-lock without using wrenches, just with operator’s hand. One of the main benefits is possibility of hole piercing by oxy-fuel technology into the steel plates up to 150 mm thickness (*). With setting of proper parameters recommended by GCE the machine can pierce the plate smoothly and safe for the equipment and environment without expensive mechanical pre-drilling.

One of the main benefits is possibility of hole piercing by oxy-fuel technology into the steel plates up to 150mm thickness (*). With setting of proper parameters recommended by GCE the machine can pierce the plate smoothly and safe for the equipment and environment without expensive mechanical pre-drilling.

The pictures are showing piercing sequence of 70 mm plate:

Material preheating, piercing process start, creation of the hole and cut-through. Focussed flame energy, robust heating nozzle and integrated Coolex® system increase the number of the hole-piercing quantity done by one set of consumables.

(*)Trained operator, proper process parameters, good cutting machine and quality and clean steel plate are required.