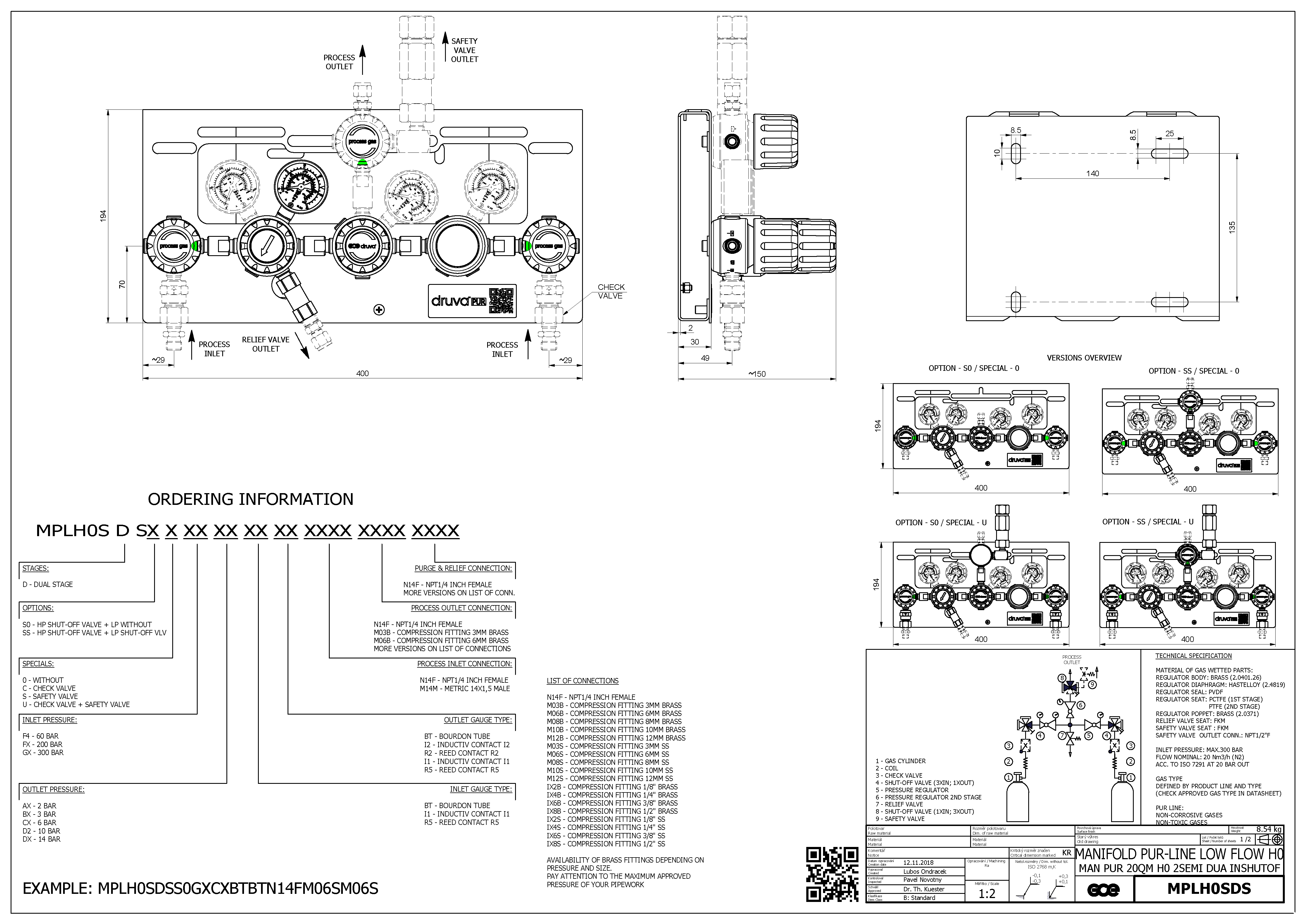

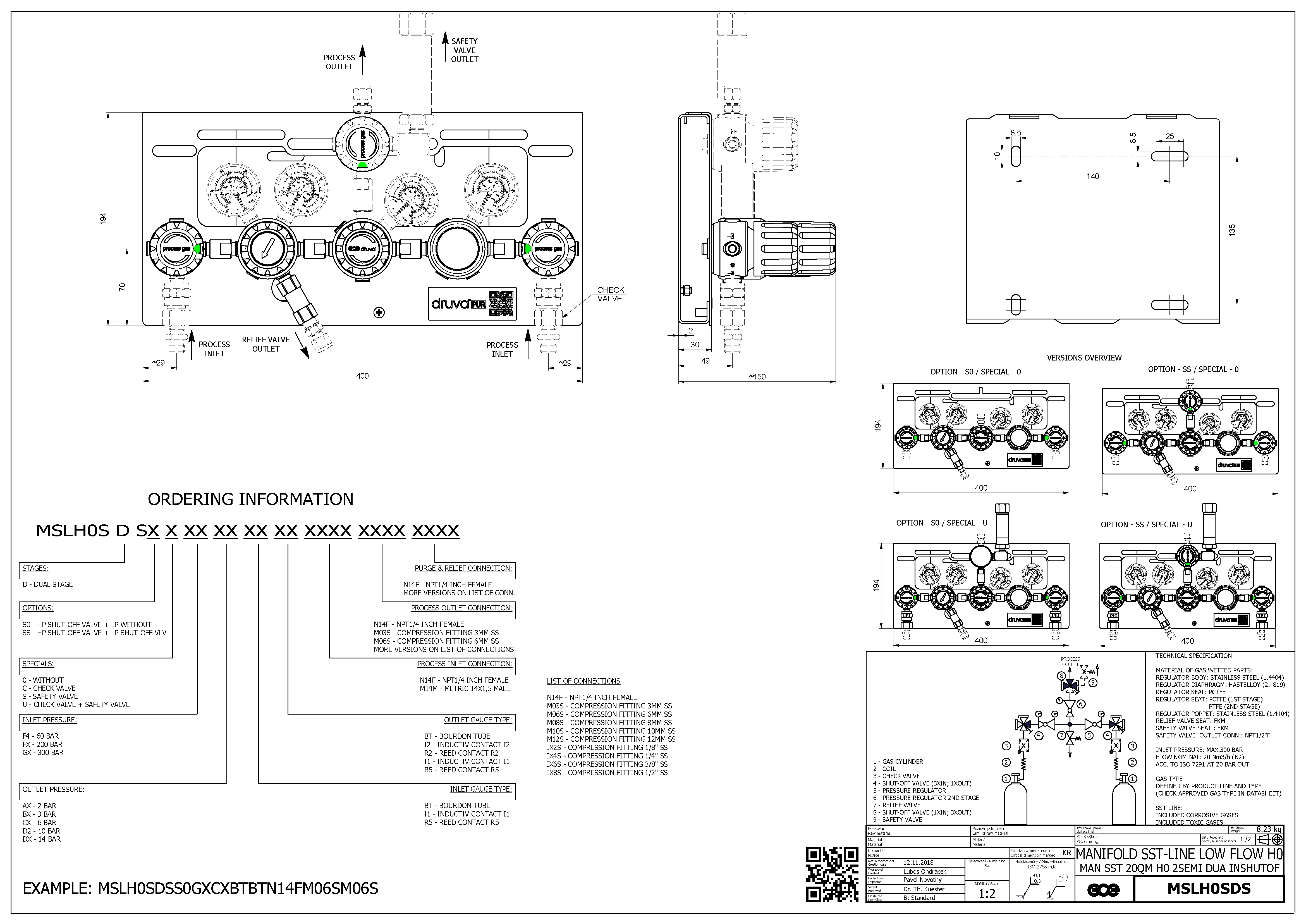

LOW FLOW RANGE - DUAL STAGE - HIGH PRESSURE VALVE

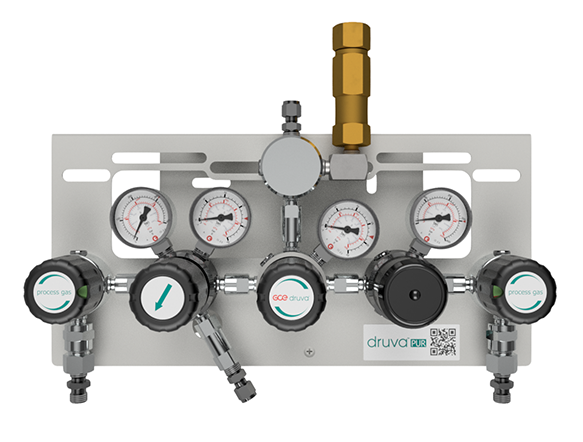

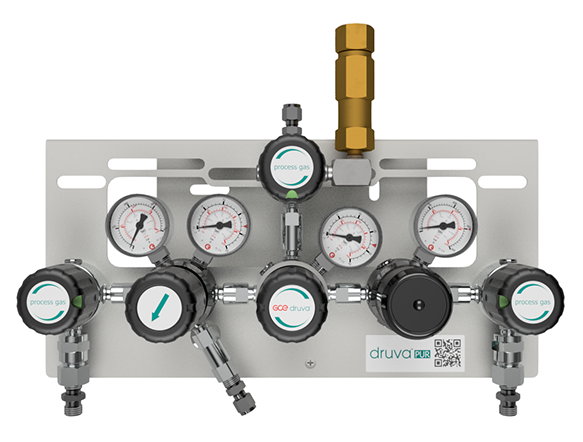

MANIFOLD FOR PURE GAS SUPPLY SYSTEMS, Two sources, Semi changeover system, High-pressure valve

The manifold used in gas supply systems for pure, inert, flammable, oxidizing gases and gas mixtures. not usable for corrosive and/or toxic gases and gas mixtures. Maximum gas purity is 6.0.

TECHNICAL SPECIFICATION

- Manifold for two gas cylinders

- Regulator and Valves - Hastelloy/Elgiloy diaphragm tighting system to atmosphere

- Compact design

- Excellent pressure adjustment

- Valves - designed and approved in accordance with relevant sections of EN ISO 10297:2015 (including O2 - ignition test for the main valve)

- Regulator - designed and approved regarding ISO7291 (including O2 - ignition test)

- A relief valve in the delivery pressure side

- Available with a shut-off valve at the outlet, safety valve at outlet check valve at the inlet

- Electrostatic chargeability test

- Fulfils requirements according to DIN EN ISO 80079-36, IEC TS 60079-32-1 and German TRGS 727

- Usable in EX-areas zones 1 and 2 for gases with explosion risk group I; IIA; IIB; IIC

SPECIAL FEATURES OF MANIFOLD

- Splitted plates of the manifold

- Separated mounting of the ground plate

- Easy mounting of the manifold to ground plate and fix with one screw only

- Front plate cutout for in-field gauge replacement

TECHNICAL DATA - MANIFOLD

| Working temperature | -20°C to +60°C |

| Material | Brass chrome plated or Stainless steel |

| Material bracket | Stainless steel |

| Flow nominal | 20 m3/h (N2) according to ISO 7291 at 20 bar outlet pressure and 41 bar inlet pressure |

| Pressure rates manifold | |

| Max. inlet pressure | 300 bar |

| Delivery pressure | 2/3/6/10/14 bar |

Technical datasheets

Direct link to druva product configurator

Technical Drawings

Top

Download Technical Drawings