BIR+™ (INJECTOR TECHNOLOGY)

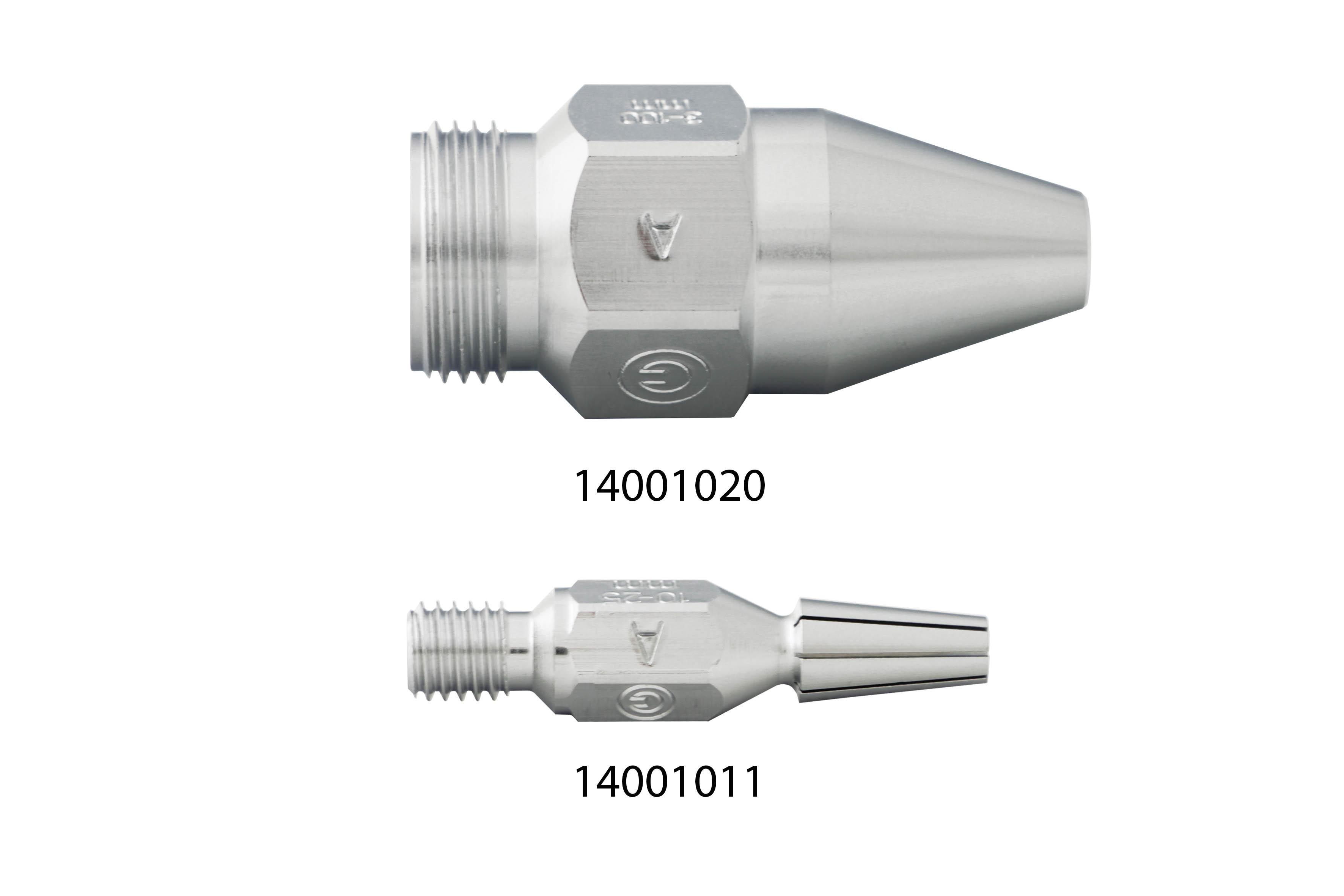

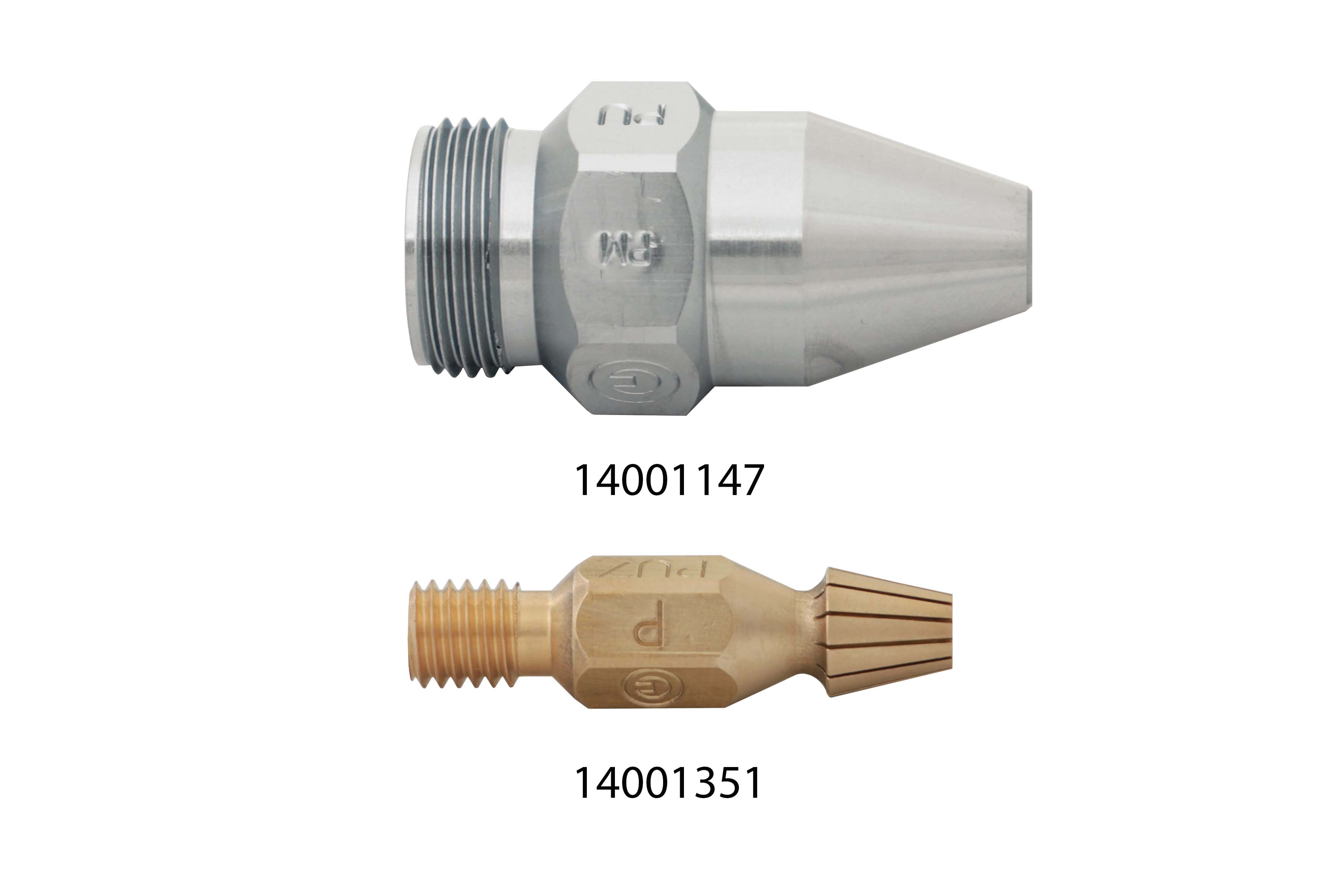

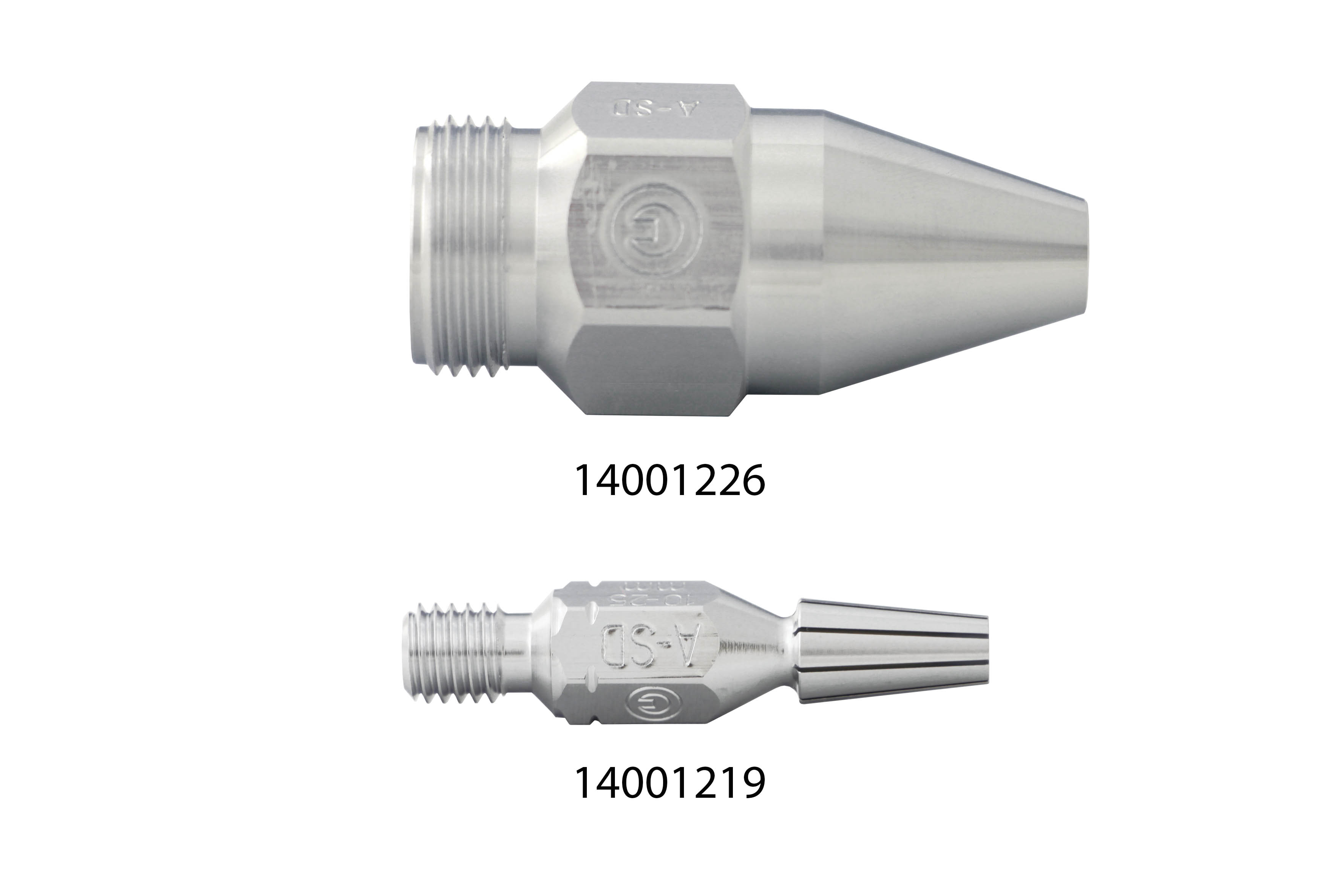

Group Number: 2531Torch is suitable for use with cutting nozzle types (Standard AC, high speed ASD, high performance AHD) for acetylene and (standard PUZ, high speed PSD, high performance PHD) for propane, natural gas and mixed fuel gases.

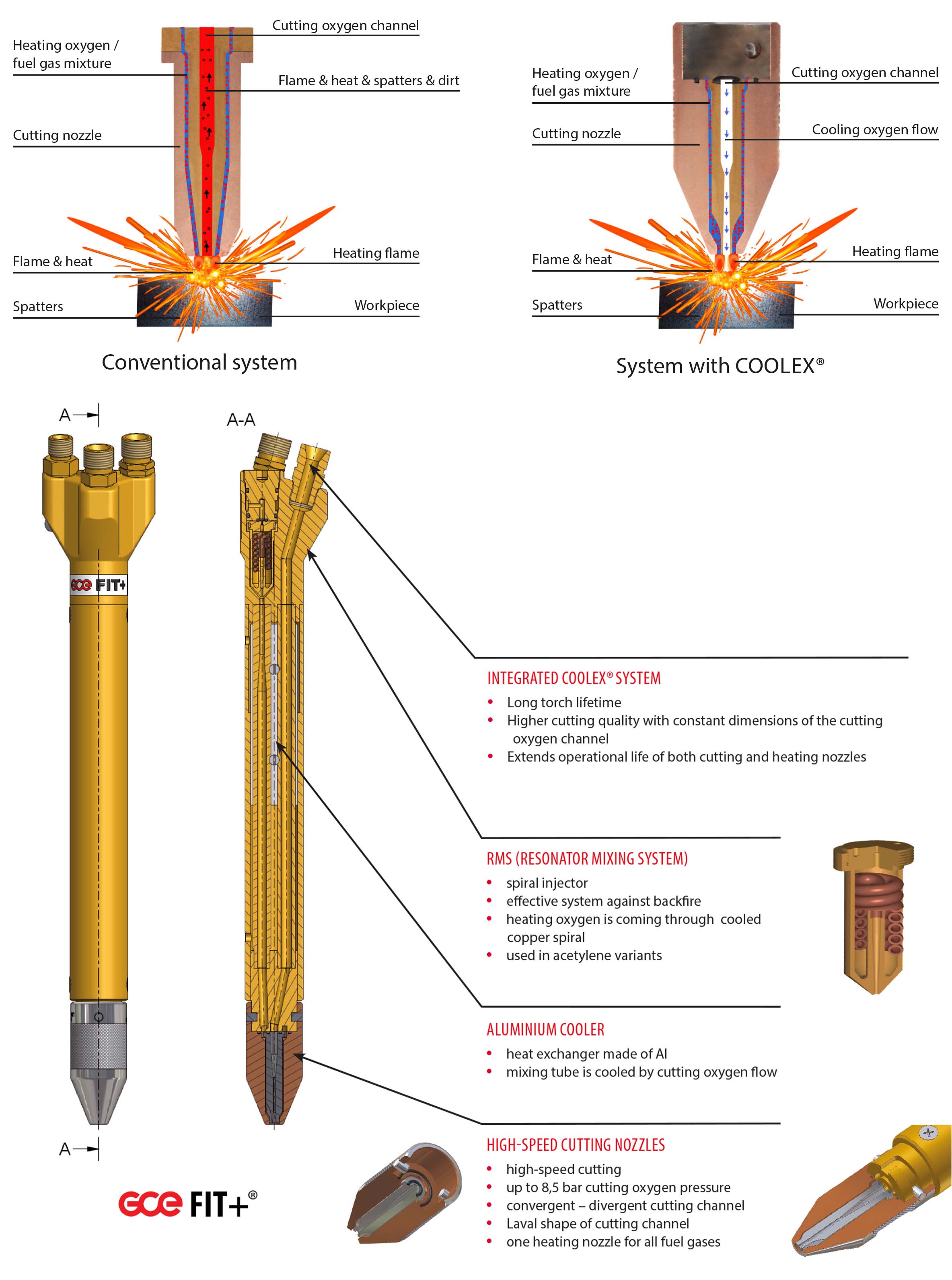

- Safe operations ensured by integrated COOLEX®

- High productivity of oxygen machine cutting process due to high-speed cutting nozzles

- Working efficiency with minimized nozzles exchange time

- Large range of cutting and heating nozzles for all fuel gases

- Long lifetime of the system

- Provided in accordance with ISO 5172

APPLICATION FIELDS

- Oxygen cutting of straight and shape cuts in accordance with ISO 9013

- Oxygen cutting 3 - 300 mm

- Hole piercing up to 150 mm

- Applications with different fuel gases

- Prepared for all cutting machines

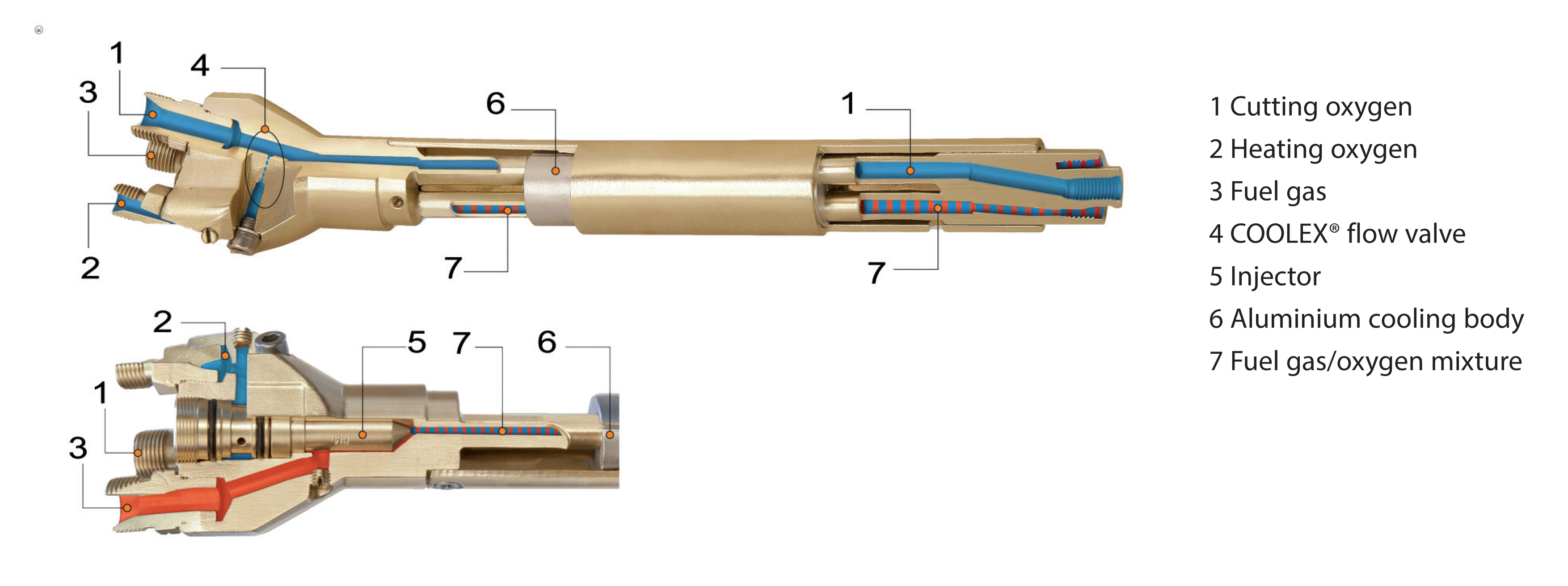

COOLEX® inside:

Unique cooling system. Stabile and safe brass injector is placed in the massive torch body. Aluminium cooling heat exchanger downstream the injector completes cooling function of the BIR+™. Heat is transported away from the injector which protects the torch against backfire. These features guarantee high process security, operation safety and long equipment life-time.

| Art. Nr. | Length / diameter | Gas | Connection |

| 14055239 | 110/32 | A | G3/8”, G3/8”LH, G1/4” |

| 14055218 | 220/32 | A | G3/8”, G3/8”LH, G1/4” |

| 14055241 | 320/32 | A | G3/8”, G3/8”LH, G1/4” |

| 14055222 | 220/30H | PM | G3/8”, G3/8”LH, G1/4” |

| 14055242 | 110/32 | PM | G3/8”, G3/8”LH, G1/4” |

| 14055219 | 220/32 | PM | G3/8”, G3/8”LH, G1/4” |

| 14055240 | 320/32 | PM | G3/8”, G3/8”LH, G1/4” |

Other lengths and diameters on customer request.

Related Products

Top

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.JPG)